About our Laser cutting

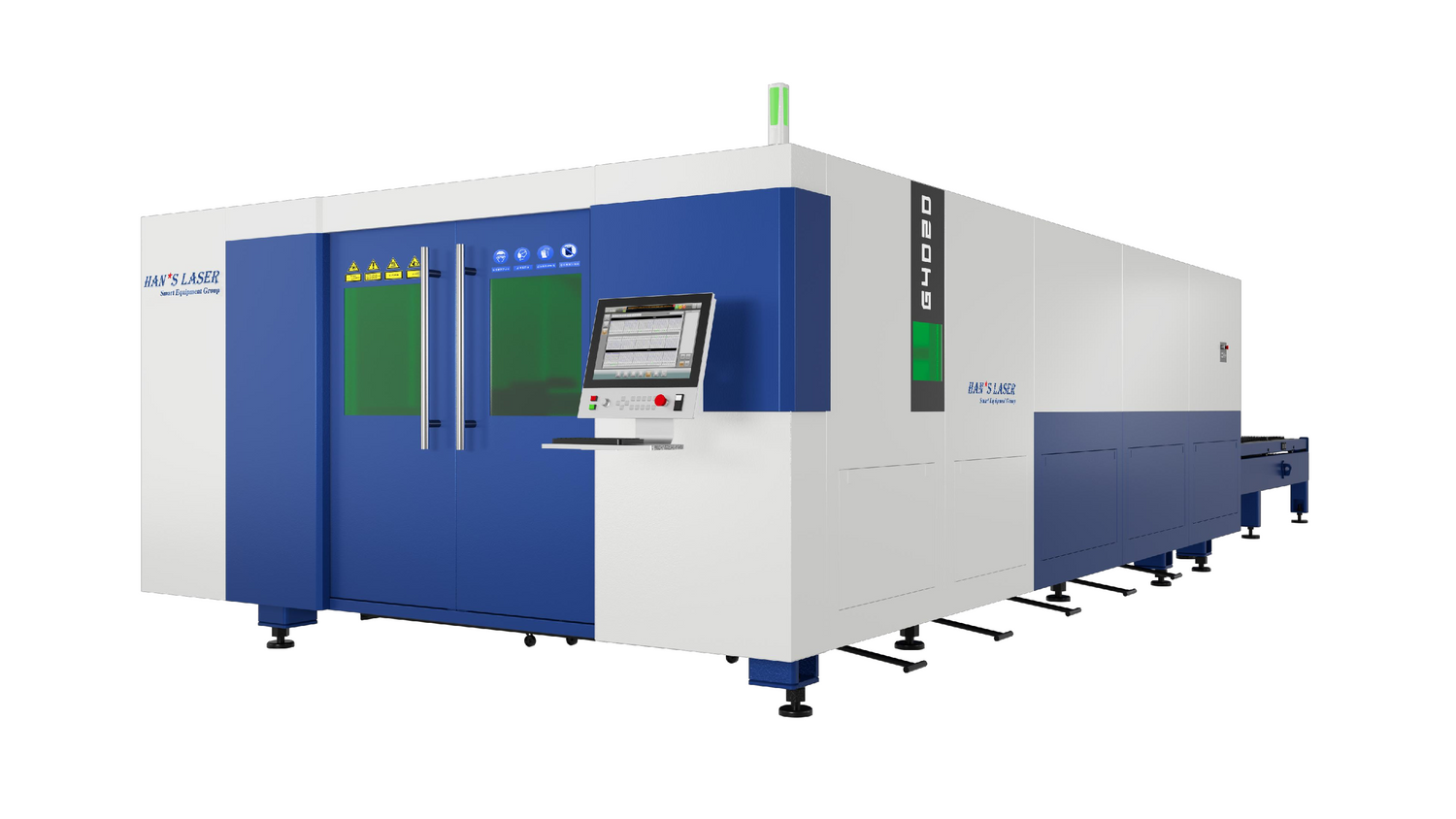

G6025 Fiber Laser Cutting Machine

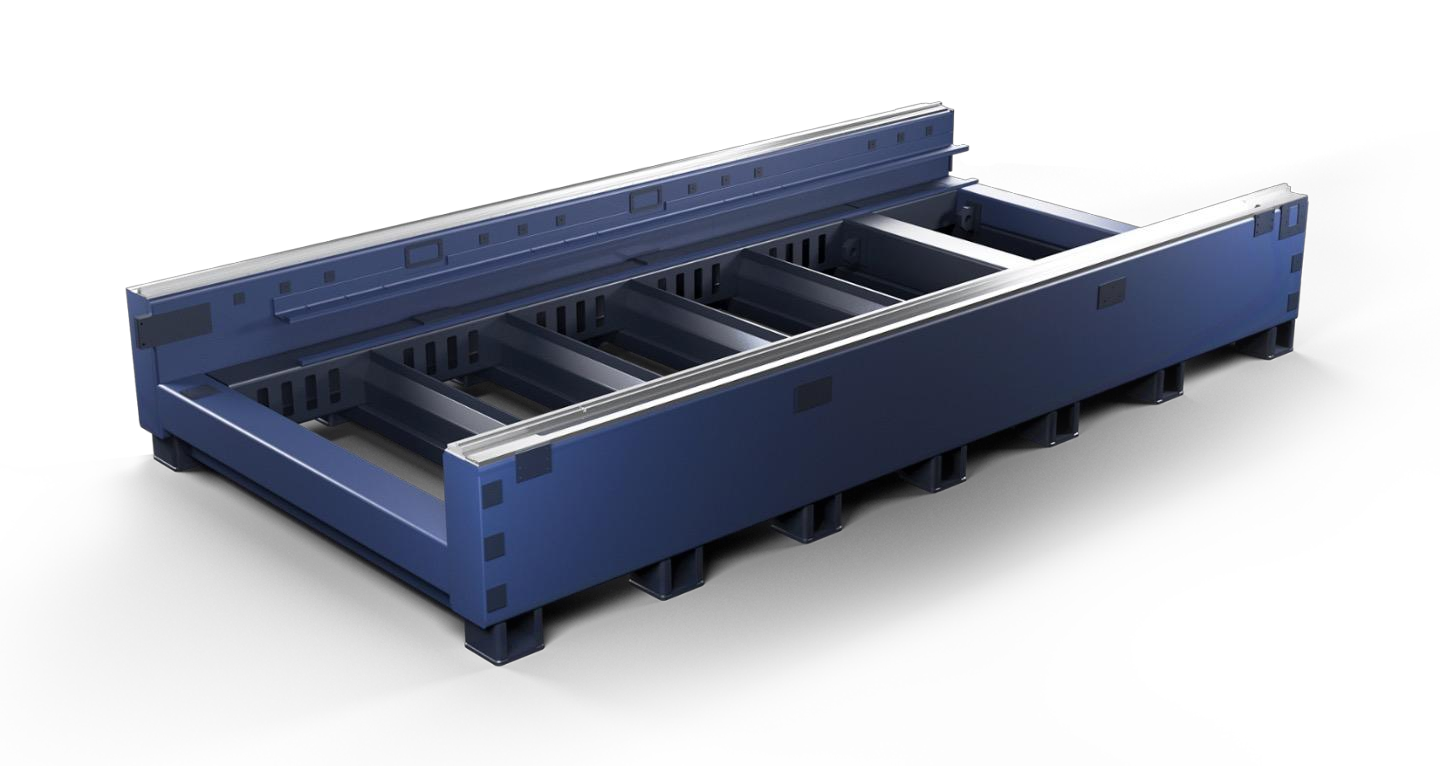

G6025 adopts the form of gantry double drive structure, the whole bed is welded and annealed by carbon steel, the beam is processed and heat treated by high-strength materials, both of which are processed by roughing, vibration aging treatment and finishing processing, achieving extremely high form and position tolerance accuracy; Transmission is equipped with well-known brands of high-rigidity precision reducer, grinding rack and pinion, high-precision linear guide and other efficient transmission mechanism, good rigidity, high precision, to ensure long-term stable operation of equipment; Through the Han's SMC bus CNC system set independently developed by Han's Laser, the precision numerical control fiber laser cutting realizes the integration of laser cutting ,precision mechanical and numerical control technology.

Video

Automatic Focusing Laser Cutting Head

Fully self-developed fiber laser special cutting head, under the strict beam shaping and mechanical design, the fixed optical ratio lens is selected, coupled with the non-contact high automatic tracking system of Han's SMC capacitor, after strict performance test, it has achieved Unanimously recognized by the market.

Video